Military specifications and ASTM standards met by Lancs plastic film materials

- NFPA 701: Fire Retardancy

- ASTM 1593: PVC Sheet Physical Properties

- L-P-375: PVC Sheet Physical Properties

- SS-481-PVC: Bags, Tubing, and Sheet Physical Properties

- MIL-STD-2041: Detrimental Material Control

- NFPA 701: Fire Retardancy

- MIL-STD 2041: Detrimental Material Control

- SS-507: Polyether Polyurethane

- ASTM D2103: PE Sheet Physical Properties

- L-P-378: PE Sheet Physical Properties

- SS-480: PE Bags, Tubing, Sheet – Transparent Yellow

- MIL-DTL-24466B: PE Bags, Tubing, and Sheet Physical Properties

- NFPA 701: Fire Retardancy

- MIL-STD-2041: Detrimental Material Control

- MIL-B-81705: Electrostatic Protective Material

Score: Covering three types, three classes and two forms of laminated or coated cloth. The cloth is intended for use in the manufacture of protective covers and tarpaulins: the laminated strip is intended for nuclear pipe insulation.

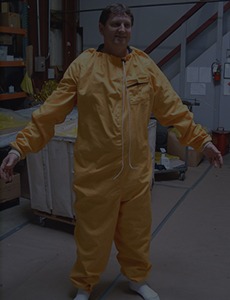

Scope: These requirements apply to flame-resistant materials that are used extensively in the interior of buildings. In protective clothing for certain occupations and situations. And for protective outdoor coverings such as tarpaulins and tents. The flame-resistant requirements are not dependent on the type off treatment; however, where durability to laundering or weathering is claimed, the fabric or film is tested for flame resistance after being subjected to the applicable cleaning or exposure procedures.

Scope: This specification covers lead pig and lead wool used for calking purposes.

Scope: This specification outlines the requirements for protective clothing materials, particularly plastic films, used in the packaging and shielding.

Scope: This document covers the requirements for pliable, green transparent polyethylene bags, sheet, tubing.

Scope: The purpose of this standard is to stablish uniform requirements for control of detrimental materials in products and equipment that come in contact with special purpose hardware.

Scope: This speciation establishes the requirements for aromatic polyurethane film: unpigmented and yellow; non-glossy and glossy surfaces. This grade of polyurethane shall be classified as the thermoplastic elastomer and shall be designated by the American Society for Testing and Materials (ASTM) designation “EU”. Where used in this specification the term “film” refers both to polyurethane film and sheet less than 0.024 inches in thickness.

Scope: this specification covers the requirements for pliable; clear (no color tint) and yellow; transparent or translucent; PVC bags, tubing, and sheet.

Scope: this specification covers nonrigid PVC plastic film and sheeting in which the resin portion of the composition contains at least 90% vinyl chloride. The film and sheeting covered herein shall be 0.075 to 0.25 mm (3 to 10 mils) in thickness for film and greater than 0.25 mm in thickness for sheeting. The film and sheeting shall include the stabilizers and plasticizers necessary to meet the requirements of the specification.

Increase Safety And Reduce Risk

View Our Extensive Product Line

Our products, including lead radiation shielding, lead-free radiation shielding and radiation containments, reduce radiation exposure and minimize the spread of contamination at nuclear power plants, Department of Energy remediation sites and laboratories, U.S. Navy ships, submarines and shipyards, and radioactive settings throughout the United States and the world.

Some of the customers we serve

Learn how we can help your business today.