Experience and innovation

Lead Radiation Shielding Blankets, Racks, & More

Lancs Industries has over 40 years of experience in the direct manufacturing of radiation shielding products. Our production and operational expertise extends to the many different shielding situations an operator or technician will encounter. From small local site shielding projects to large scale refueling outages, we can advise on the best materials to use and can manufacture any configuration for lead blankets to best address your requirements. Lancs has manufactured over 80% of the lead wool blankets in use in nuclear power plants in the United States today. In addition to our lead shielding products and lead blanket racks, we also produce non-lead radiation shielding and many other radiation protection products.

LEAD WOOL BLANKETS FOR RADIATION SHIELDING

Lead anti-radiation blankets are constructed with lead wool or lead plate. Lead wool consists of fine strands of lead from .005 to .015 inch diameter, of varying length. Lancs uses lead wool products in accordance with Federal Specification QQ-C-40 Type II Grade C. We compact this interlaced wool in a random orientation to ensure consistent attenuation without streaming. Since lead wool is by nature less dense than lead plate/sheet, the mass equivalence and approximate dose rate reduction for various densities is shown in this table:

| LEAD WOOL | APPROX. FINISHED | %DOSE RATE |

|---|---|---|

| Density (Ib/sq ft) | Blanket Thickness (in) | Reduction (60 Co) |

| 10 | 3/8 | 25% |

| 12.5 | 1/2 | 32% |

| 15 | 5/8 | 35% |

| 20 | 3/4 | 44% |

The mass equivalence and approximate dose rate reduction for various densities of lead plate/sheet is shown in this table:

| LEAD SHEET/PLATE | APPROX. FINISHED | %DOSE RATE |

|---|---|---|

| Density (Ib/sq ft) | Blanket Thickness (in) | Reduction (60 Co) |

| 7.5 | 1/8 | 19% |

| 9.25 | 5/32 | 23% |

| 11 | 3/16 | 27% |

| 15 | 1/4 | 35% |

Lead Radiation Shielding Details

We can produce shielding blankets made from both lead wool and lead sheet/plate.

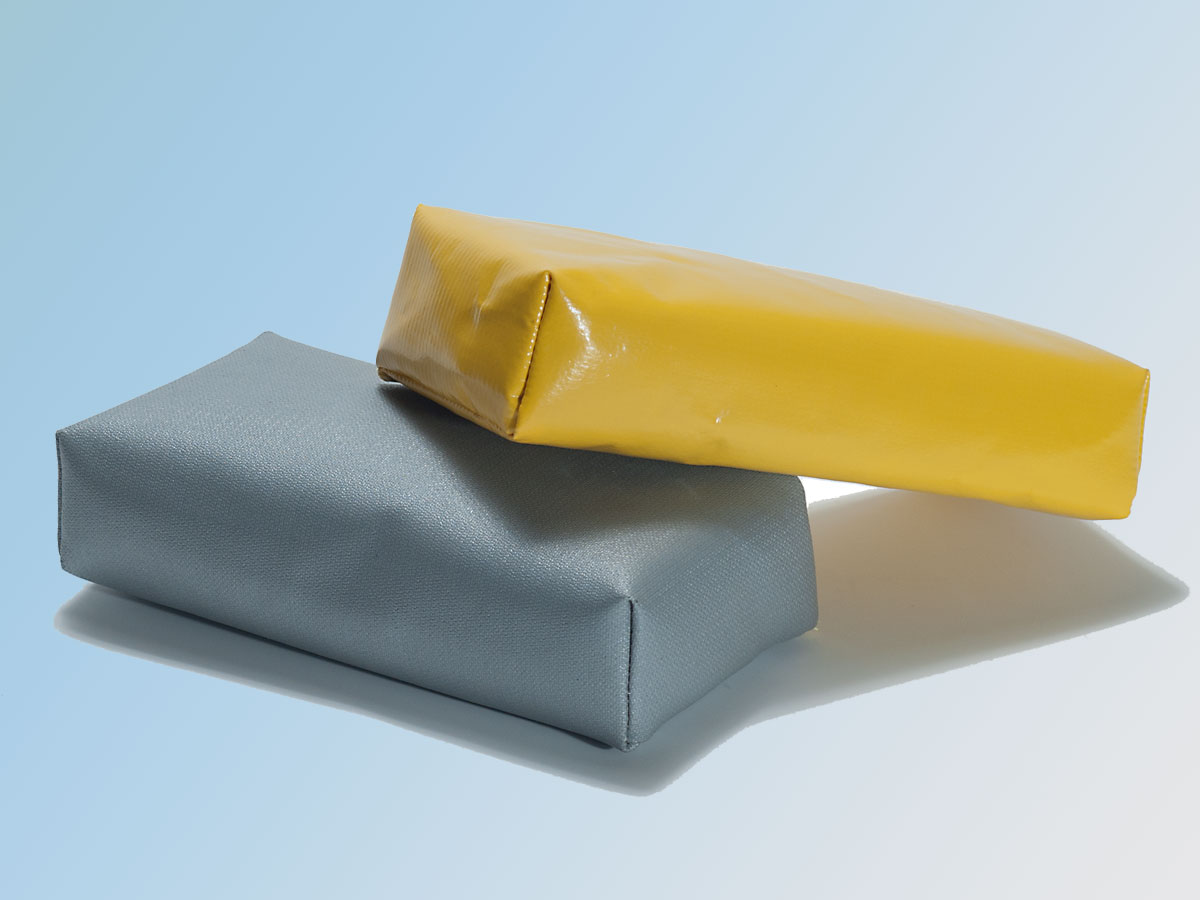

Lead wool blankets are more pliable than lead sheet, and are an optimal choice for set-ups that require a flexible or adaptable configuration

How to achieve a reduction in dose rate.

Where greater shielding is required, multiple blankets can be stacked to achieve a higher dose reduction.

Radiation Shielding Material Construction

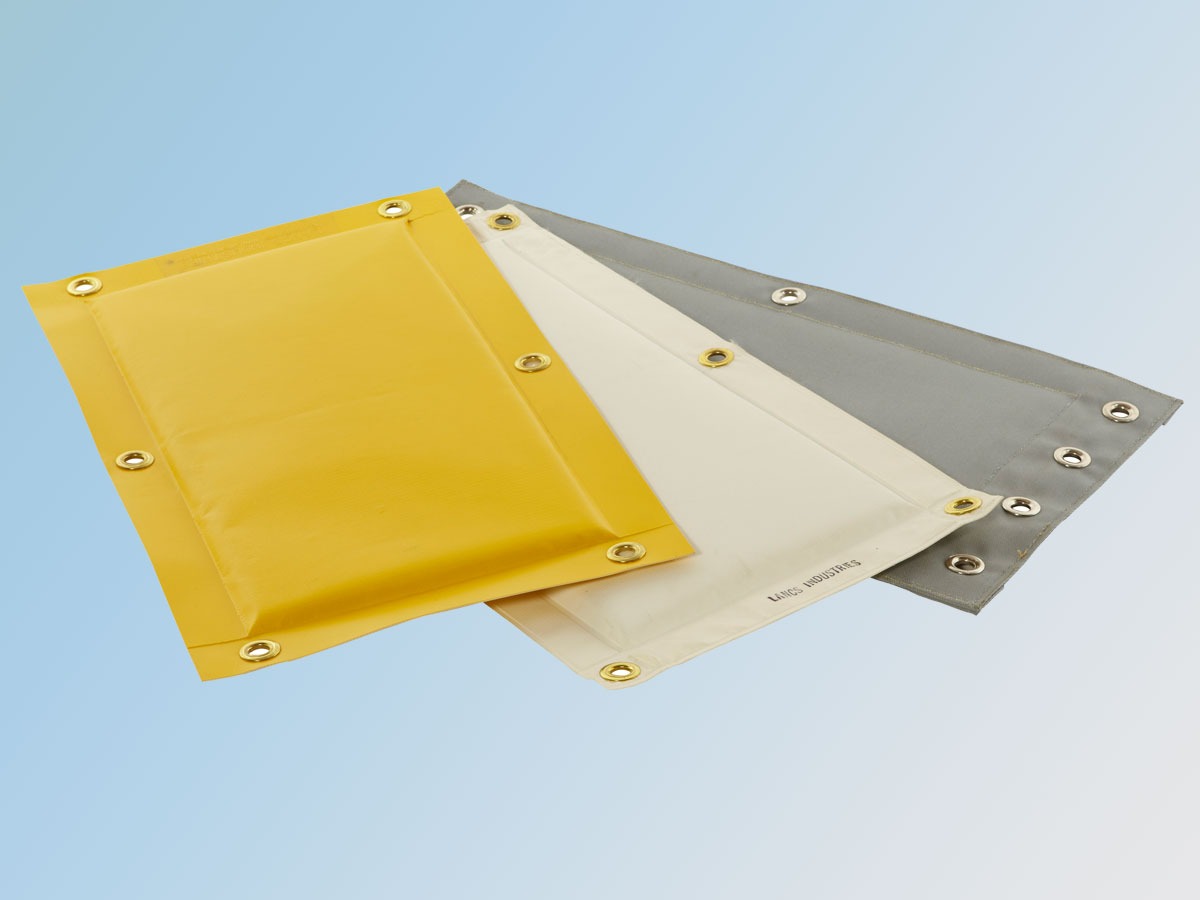

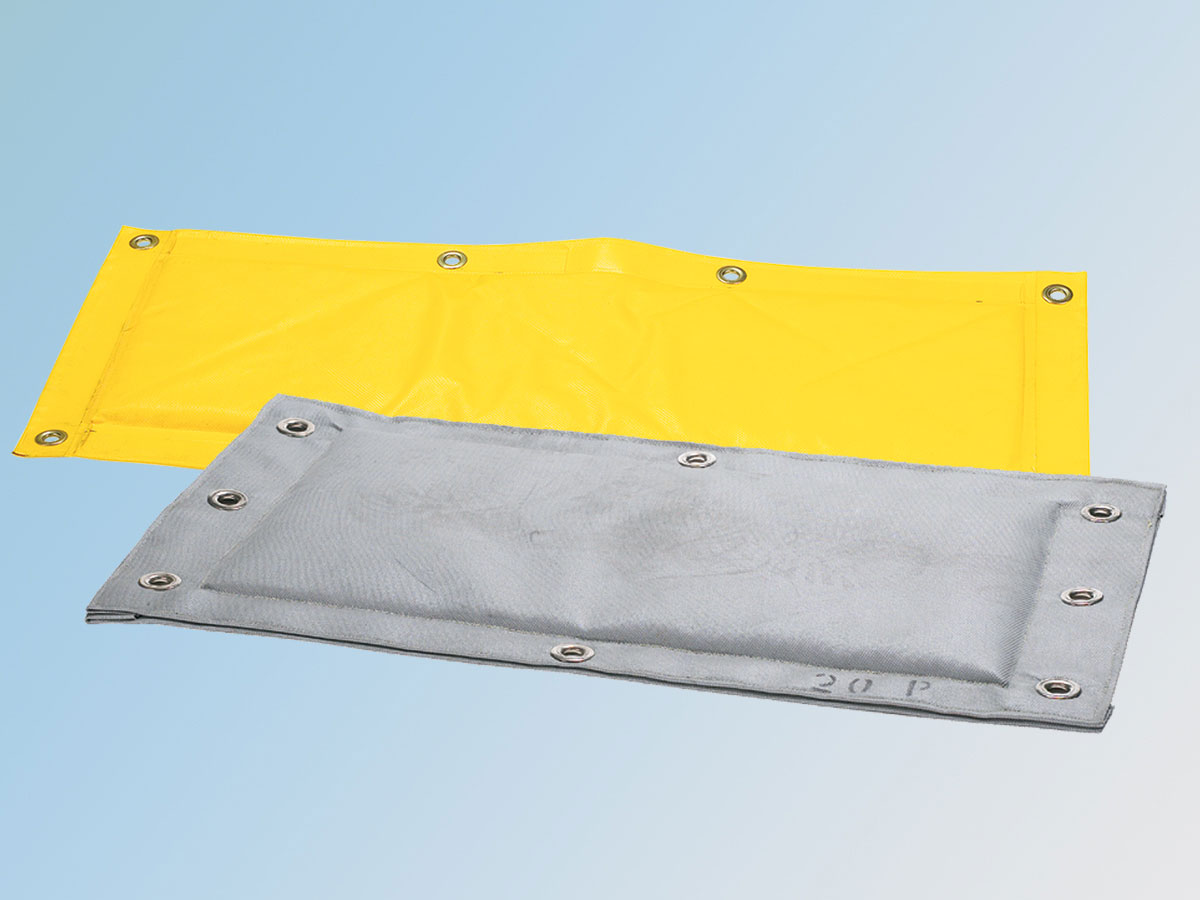

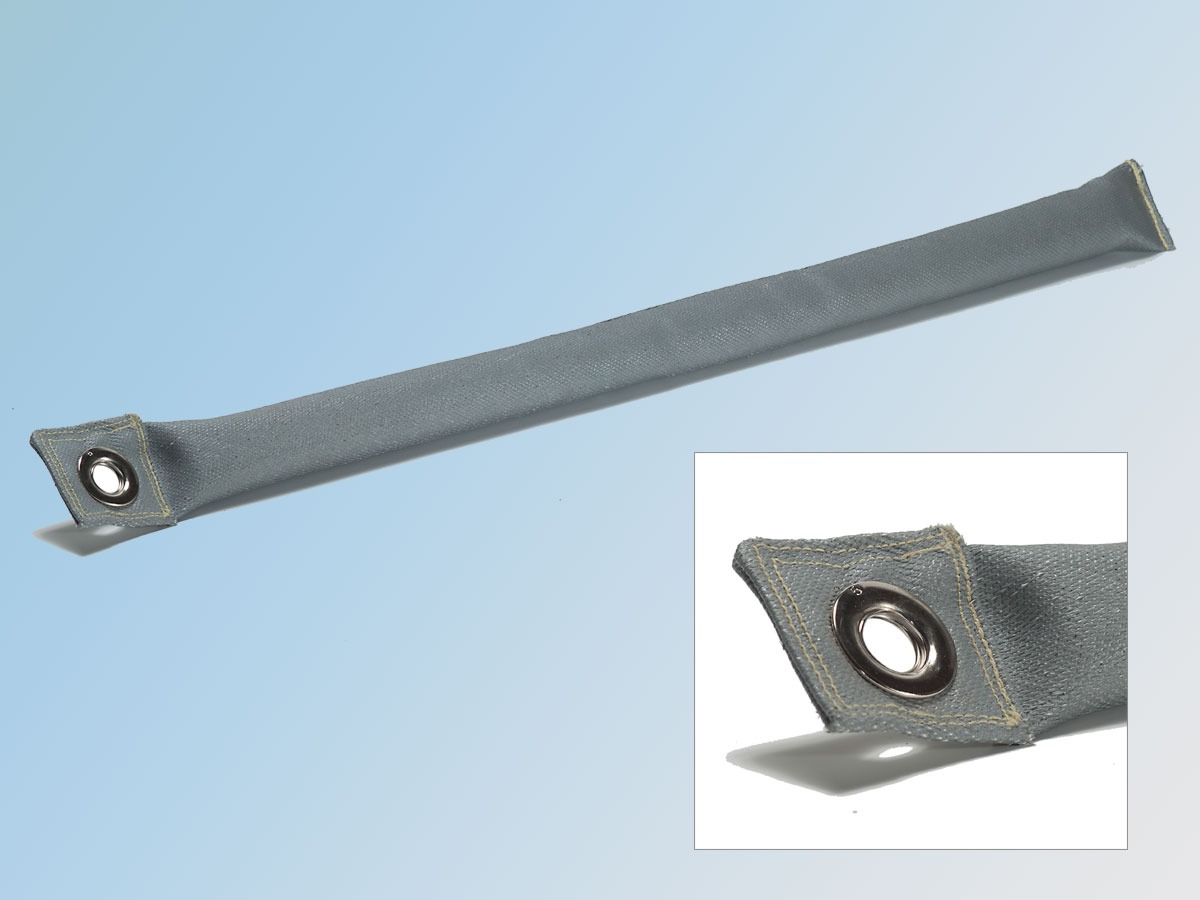

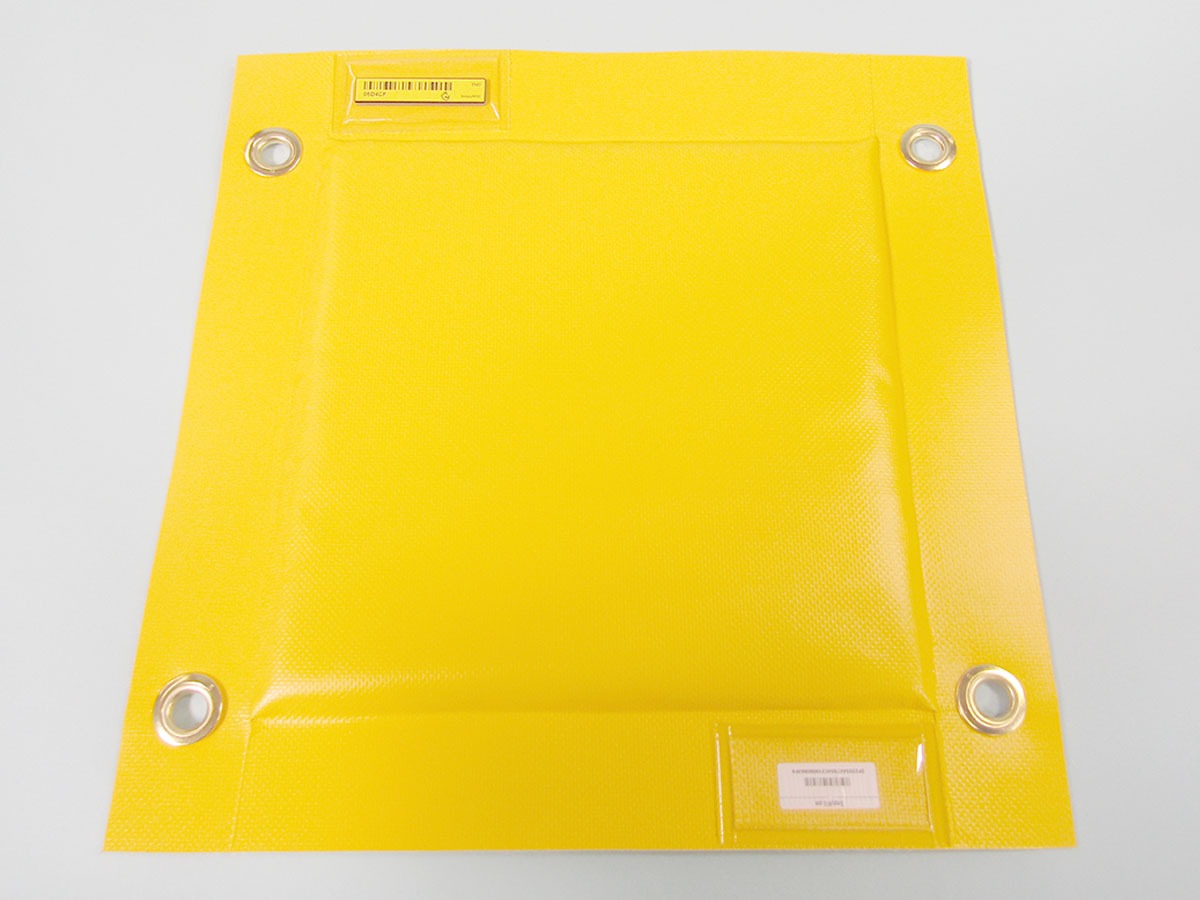

All lead blankets are constructed by encapsulating the lead within an inner cover to contain the lead, and then a heavier outer cover for added protection and durability. Materials used for inner and outer covers can be vinyl-laminated nylon, urethane-laminated nylon, or silicon-impregnated fiberglass fabric (for high temperatures.)

Inner covers of Lancs Industries lead wool blankets are sewn in a quilted pattern to prevent shifting of the lead wool when blankets are draped or hung. The materials used for inner covers are typically 10 oz. weight, with heat sealed seams or sewn seams as appropriate.

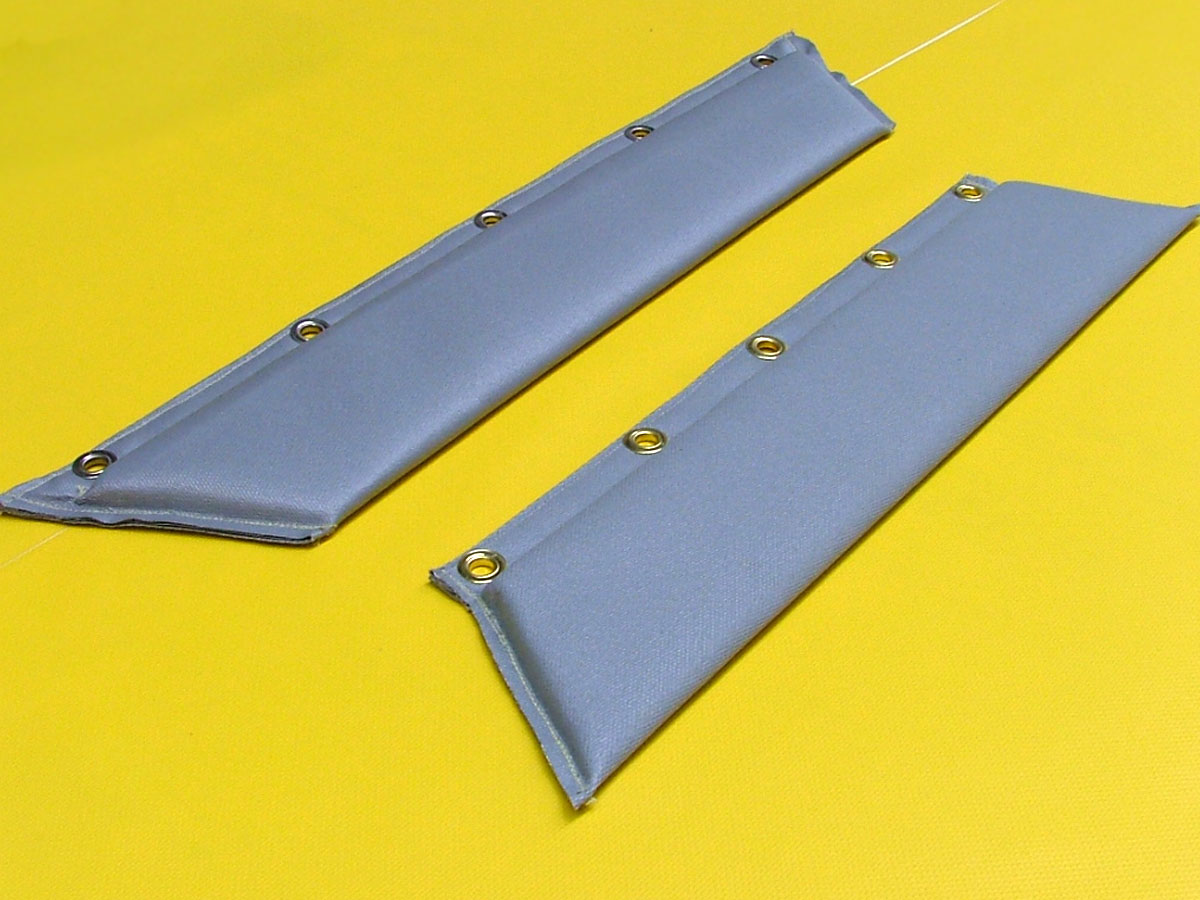

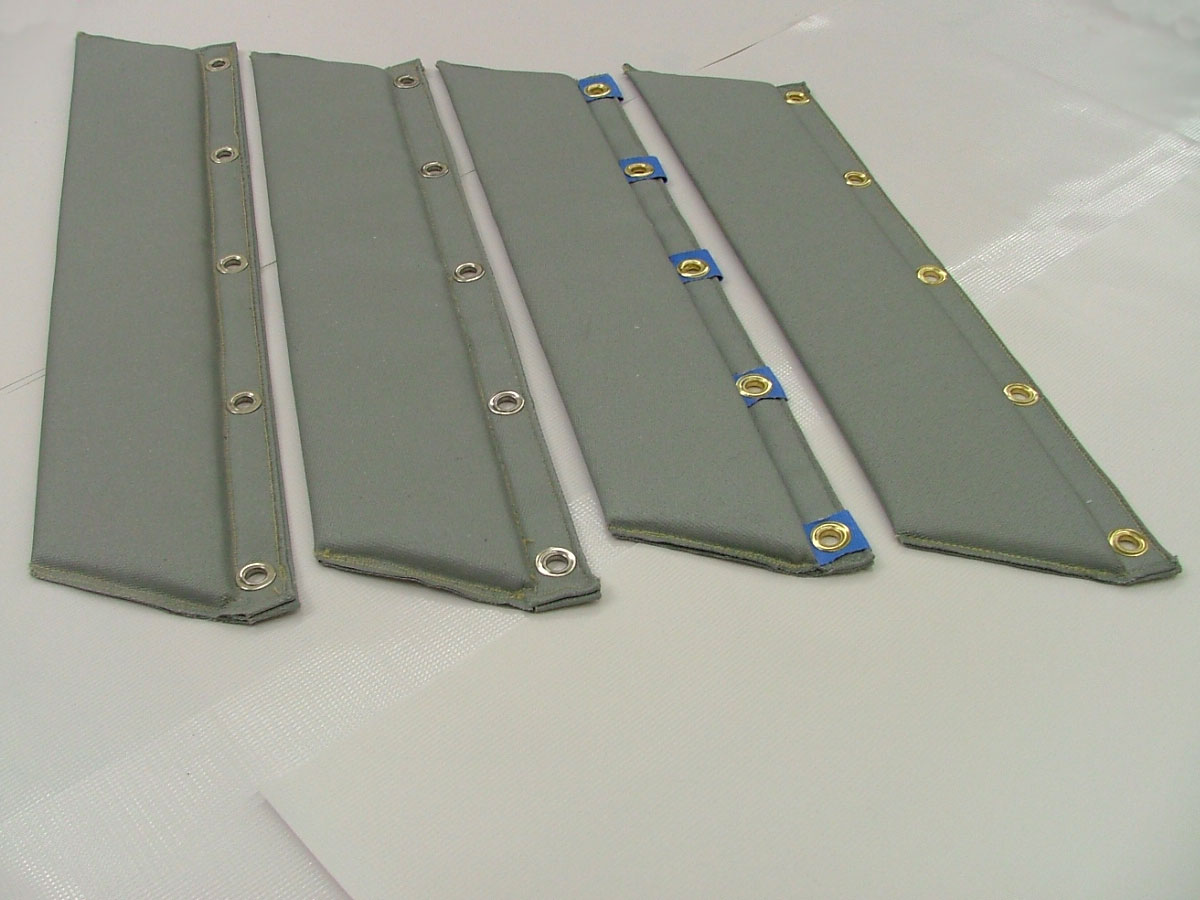

Outer covers are made using heavier weight material (typ. 18 oz.), with edge seams heat sealed or sewn as required. Perimeter grommets are installed on the outer cover border edge to facilitate job site placement or hanging from racks. Number 5 grommets (5/8” ID) at 12” spacing are standard. Grommet size, type and spacing can be as specified by your requirements. Standard colors for vinyl-laminate materials are yellow or white, with others available upon request.

Standard color for high temperature material is gray.

Weight of Radiation Shielding Blankets

The approximate weight of the blankets we produce can be determined by multiplying the dimensions of each blanket by the density – i.e., a 1 ft. x 3 ft. blanket with 15 pounds of lead wool per sq. foot will weigh approximately 45 pounds. A 2 ft. x 3 ft. blanket with 10 pounds of lead wool per sq. foot will weigh approximately 60 pounds, etc.

Note: Radiation Shielding dimensions indicate size of lead wool “cake.” Outer border edge with grommets extends about 2” beyond lead on all sides. Lancs Industries also manufactures lead plate blankets in rectangular and gore (tapered) shapes upon request.

| DIMENSION | 10 Ib/sq ft | 12.5 Ib/sq ft | 15 Ib/sq ft | 20 Ib/sq ft |

|---|---|---|---|---|

| 1′ x 2′ | LI-202 | LI-212 | LI-222 | LI-232 |

| 1′ x 3′ | LI-203 | LI-213 | LI-223 | LI-233 |

| 1′ x 4′ | LI-204 | LI-214 | LI-224 | LI-234 |

| 1′ x 5′ | LI-205 | LI-215 | LI-225 | LI-235 |

| 1′ x 6′ | LI-206 | LI-216 | LI-226 | LI-236 |

Advantages of Lead Shielding for Radiation

Lead is the most widely used radiation attenuating material. It’s a popular choice for shielding due to its unique position as being reliable, low-cost, and versatile. Lead’s high density, along with its high atomic number and stable isotopes, make it exceedingly effective at attenuating gamma and x-ray radiation.

Lead’s reputation as a cost-effective and dependable

Lead’s reputation as a cost-effective and dependable radiation protection material has led to its regular use in shielding scenarios ranging from small projects to large industrial plants, across the fields of medicine, nuclear power, scientific research, and security.

Lead is an incredibly versatile material

Lead is an incredibly versatile material, allowing the construction of lead blankets for shielding to be customized for your unique needs, specifications, and budget. Lead is known to be a remarkably malleable metal that can be easily manipulated and shaped without breaking. With a density of 11.34 g/cc, approximately four times that of other metals, such as aluminum, as well as a low melting point of 327°C, lead is uniquely ideal for casting. Lancs produces its own lead wool used in our shielding blankets.

How lead sheets are formed

Lead is an incredibly versatile material, allowing the construction of lead blankets for shielding to be customized for your unique needs, specifications, and budget. Lead is known to be a remarkably malleable metal that can be easily manipulated and shaped without breaking. With a density of 11.34 g/cc, approximately four times that of other metals, such as aluminum, as well as a low melting point of 327°C, lead is uniquely ideal for casting. Lancs produces its own lead wool used in our shielding blankets.

Lead’s pliability is also demonstrated in our lead wool blankets

Lead’s pliability is also demonstrated in our lead wool blankets, where fine strands of lead wool are meticulously compressed to guarantee uniform attenuation throughout the blanket.

Lead Radiation Shielding Solutions

From small local site shielding projects to large scale refueling outages, we can advise on the best materials to use and can manufacture any configuration for lead blankets to best address your requirements.

Lead Wool Blankets

Lead blankets are constructed with lead wool or lead plate. Lead wool is the preferred material due to its flexibility in handling. Lead wool consists of fine strands of lead from .005 to .015 inch diameter, of varying length.

LI-200-P – Lead Plate Blanket

LI-200-GORE – Lead Plate Blanket, Gore Shape

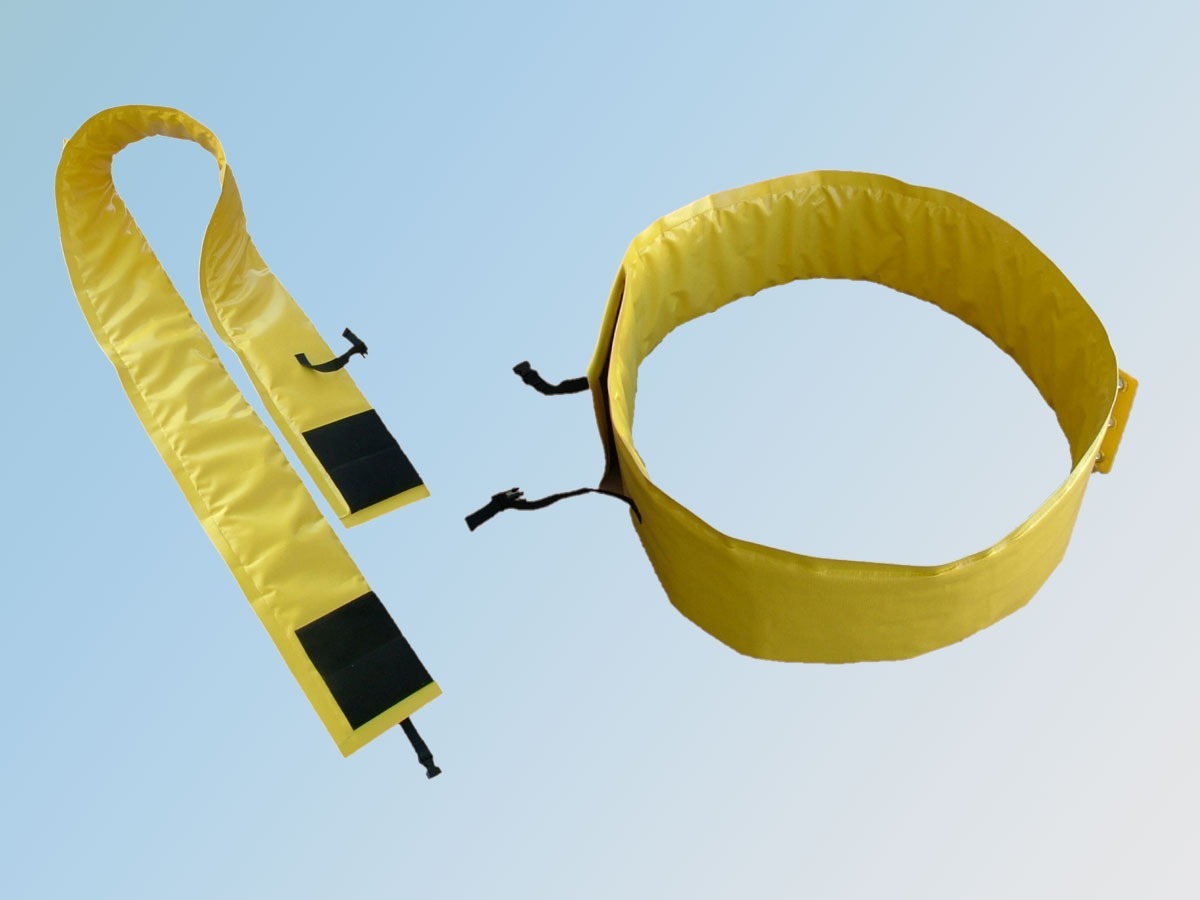

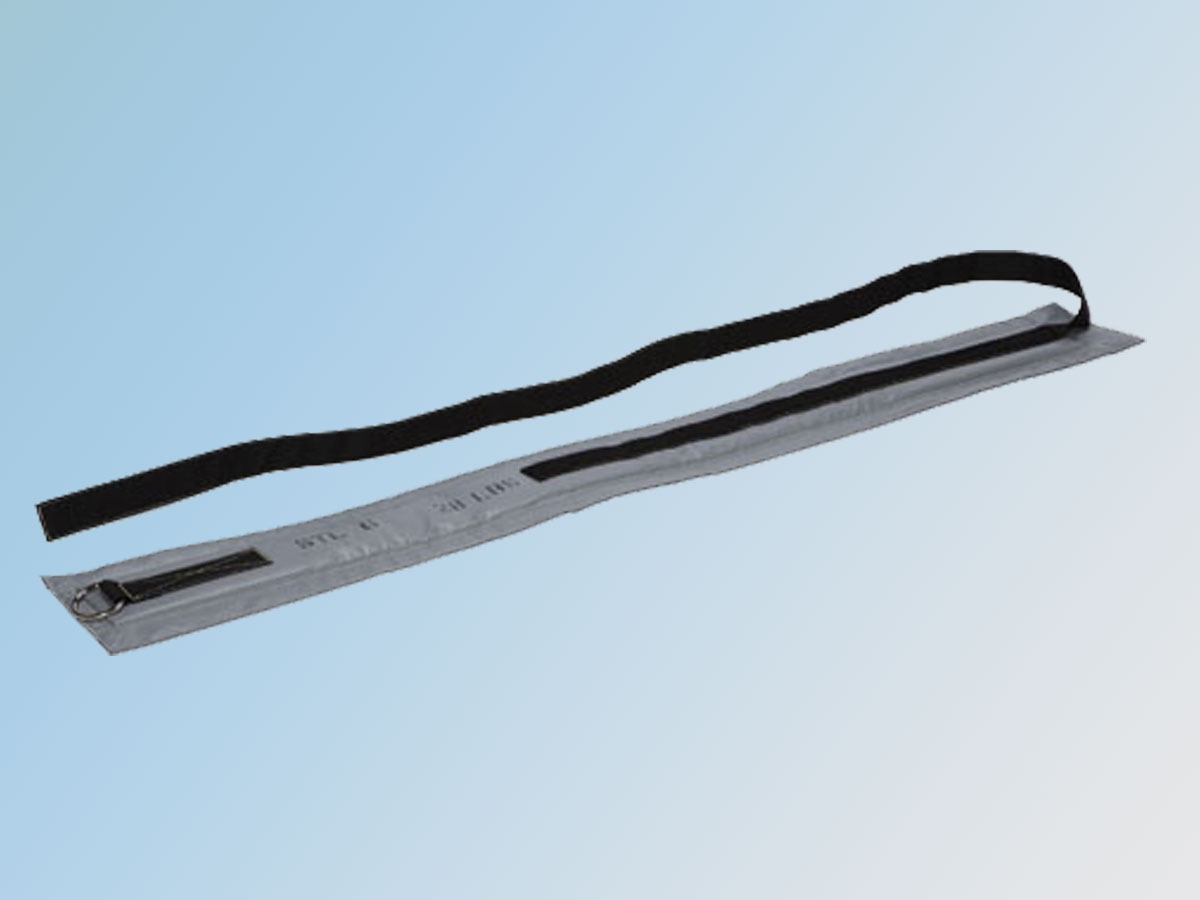

LI-200-LS – Lead Snake

LI-200-LW – Lead Wool

LI-261 Wheeled Rack

Wheeled racks are the backbone of versatile radiation shielding solutions in an industrial workspace. These racks can be transported anywhere within the plant and create configurable partitions, servicing the requirements of your specific process and space.

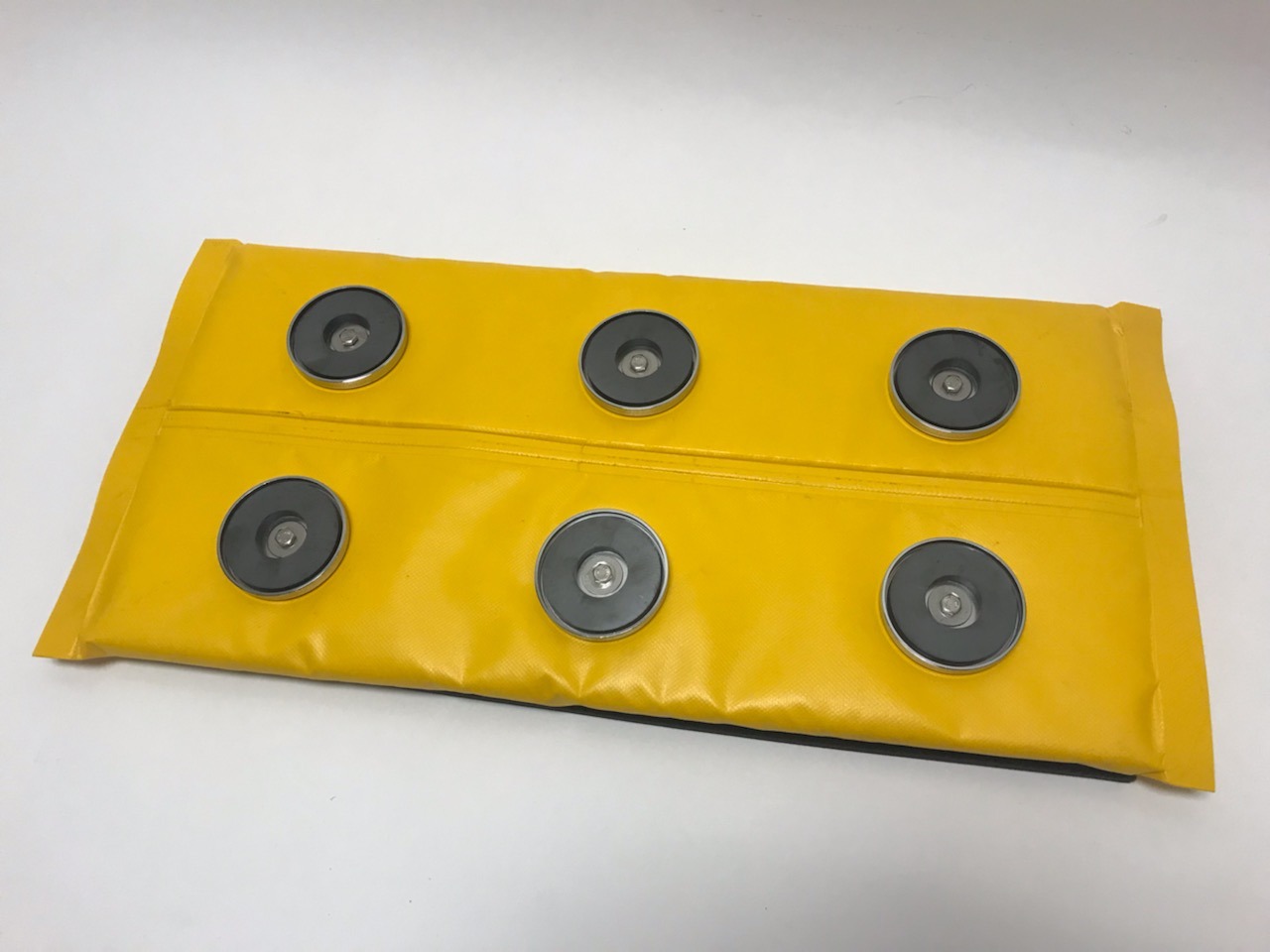

Lead Blankets with radio frequency identification (RFID) chips

Lancs QuickRack

The Lancs Industries QuickRack is a versatile new tool for your ALARA toolbox. It provides users an inexpensive, lightweight, and alternative way to quickly hang shielding and protect workers from sources of ionizing radiation. Whether used as a shadow shield around a worker or to create a shield around a source, it allows the user to readily construct and deconstruct a temporary shield in just minutes with minimal resources. Where traditional steel racks may be too large or cumbersome to deploy, the lightweight and modular design of the QuickRack allows for easy setup, breakdown and moving to virtually any area of the plant – from narrow Pipe Chases and Valve Galleries to Steam Generator Eddy Current Platforms. It weighs less than 50 pounds total and is comprised of 2 pieces (25 lbs each piece), allowing for easy access into rooms with narrow doorways. The QuickRack saves the user time and reduces dosage, cutting labor costs for your facility. This tool has been recognized by INPO as strength in the shielding program at Braidwood Nuclear Plant.

LI-200LB – Lead Brick

Lead brick shielding is a select choice where temporary or permanent shielding for storage areas is required. Lead bricks are ideal for adding additional shielding to existing rooms and can be used for walls, partitions, and transportation of radioactive materials.

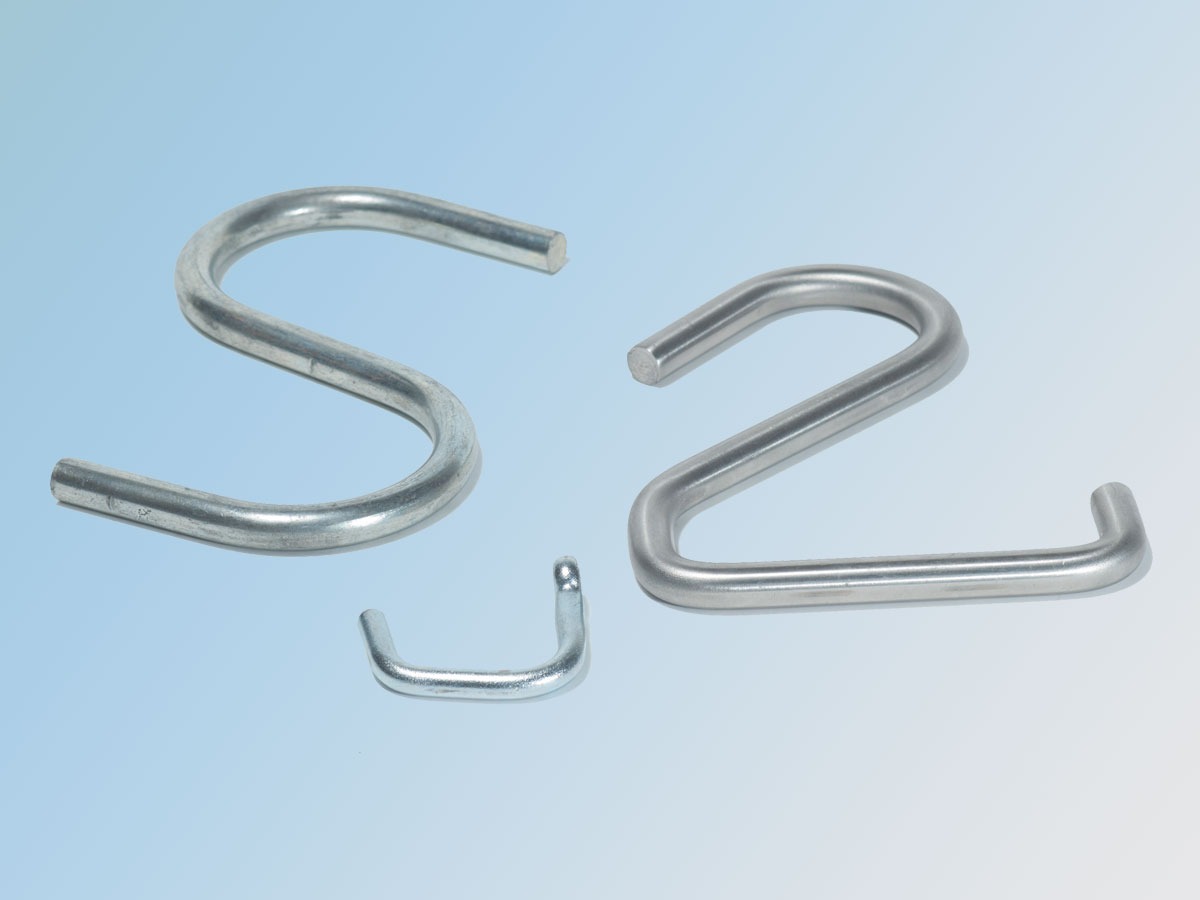

Hooks

Choose Lancs Industries for Lead Blankets for Shielding

Since we began producing our own lead wool in 1980, Lancs Industries has been the leading expert in lead radiation shielding and lead-free radiation protection solutions. Regardless of your project's requirements, our team of qualified experts can advise on the best materials to use for lead shielding products, and can manufacture any configuration for lead blankets to best address your radiation protection needs. We provide lead shielding solutions for many dose reduction jobs, and our lead products are Federal Specification QQ-C-40 Type II Grade C compliant. With Lancs Industries, you never have to compromise quality for affordability.

FAQs for Lead Shielding

Lead Radiation Shielding Solutions

From small local site shielding projects to large scale refueling outages, we can advise on the best materials to use and can manufacture any configuration for lead blankets to best address your requirements.