Contain Contamination

CONTAINMENT TENTS, TENT ACCESSORIES, AND VENTILATION UNITS

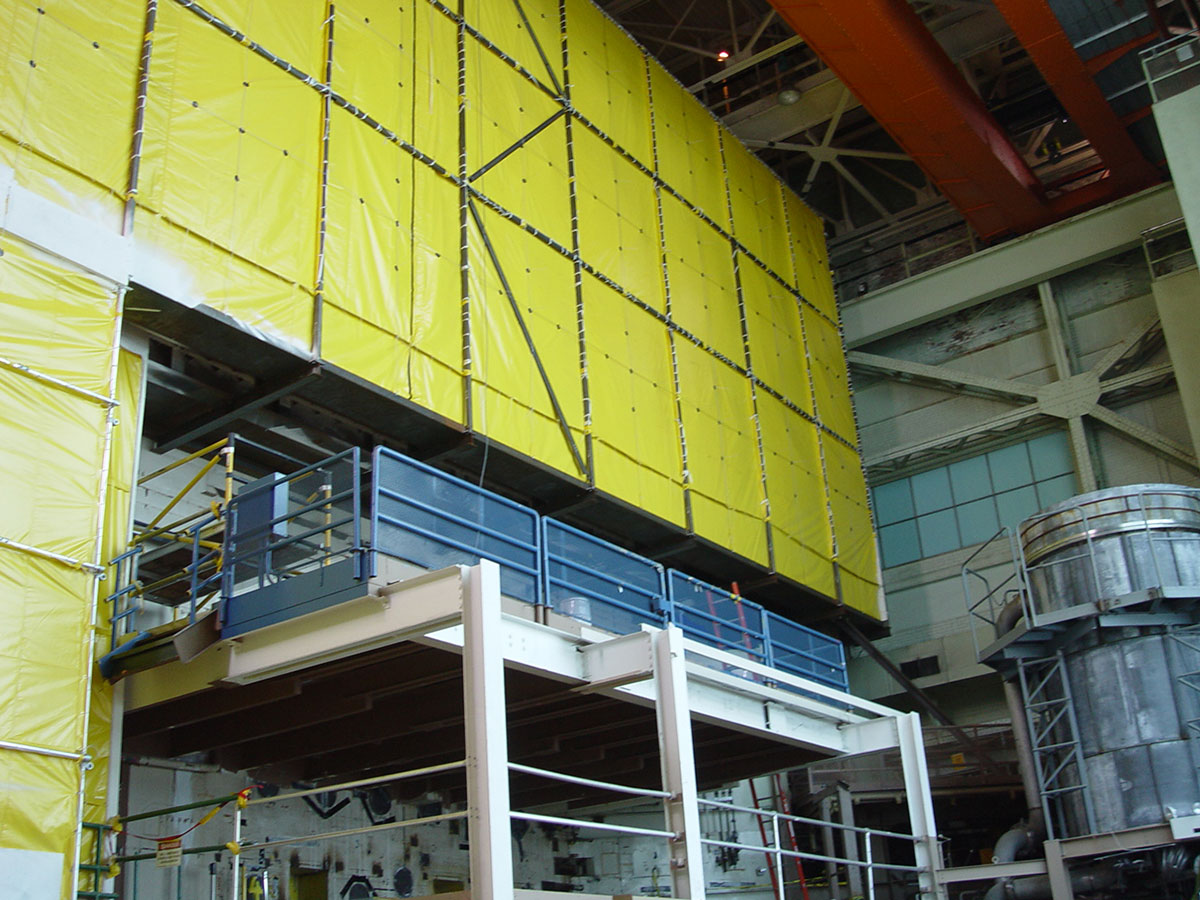

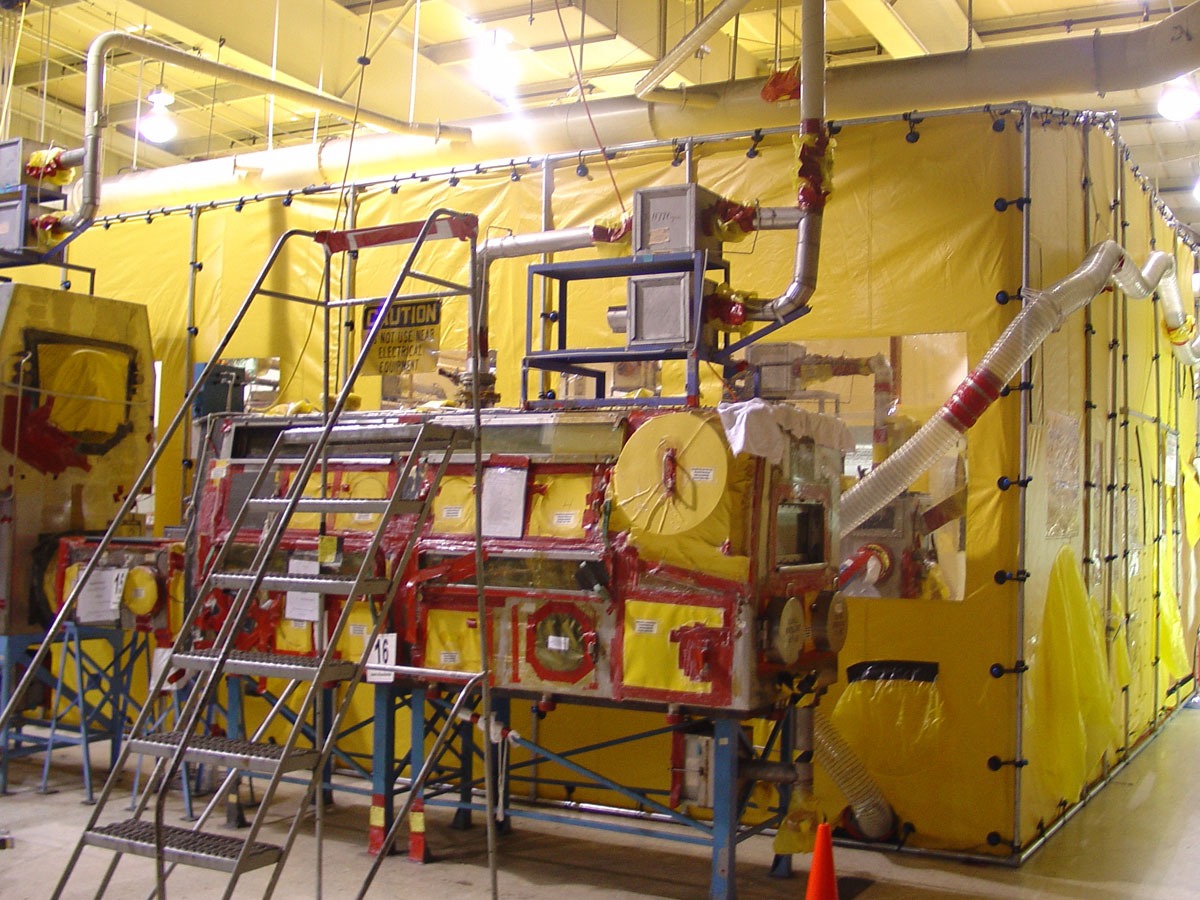

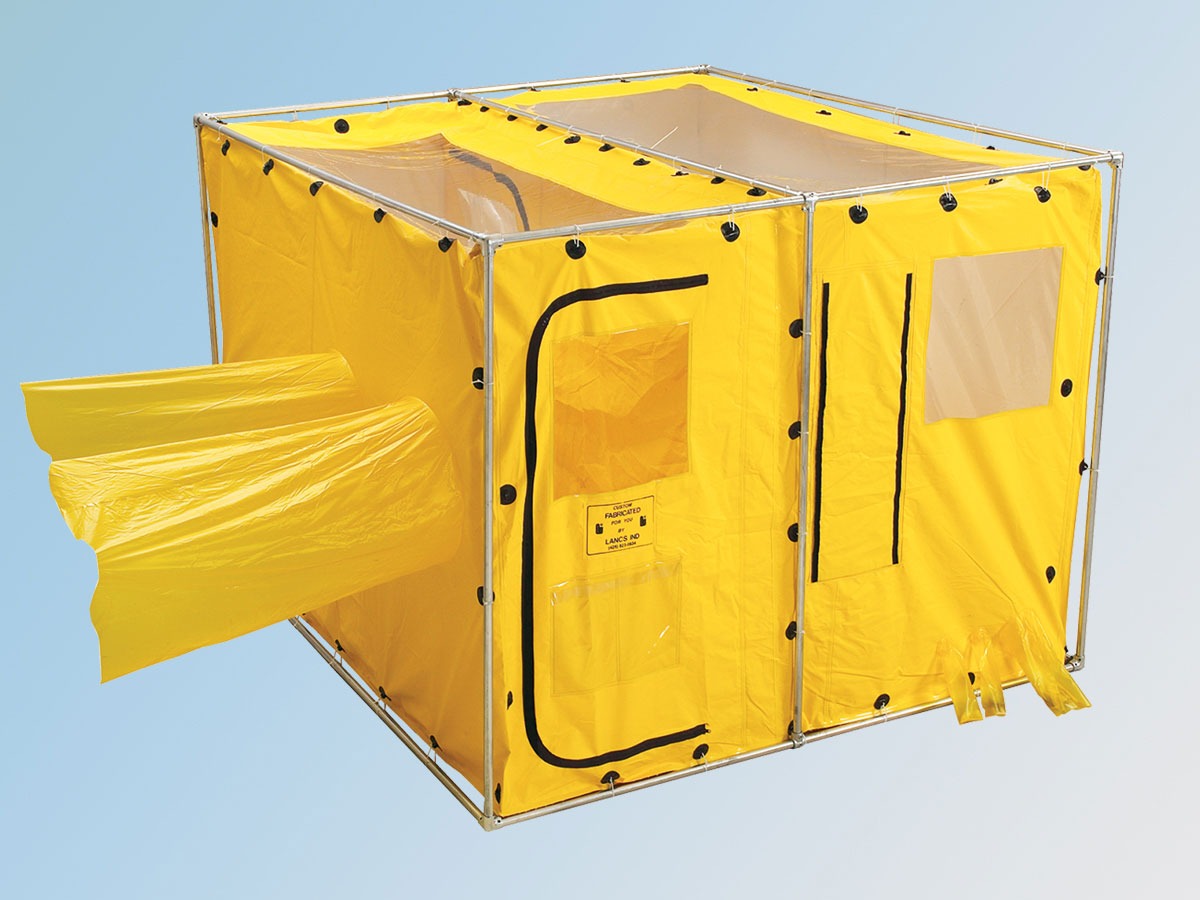

Properly designed work tents will reduce cross-contamination from work being done on structures or spaces contaminated by radiological or other hazardous materials. Serving as a barrier between work surfaces and clean areas, containment tents and covers are used to create a controlled environment to reduce overall exposure levels during work, and to minimize the scope and complexity of subsequent cleanup operations.

Lancs Industries has been providing work tents for our customers since the company’s inception in 1974. We have been involved with hundreds of different site configurations ranging from simple single chamber tents with limited access to complex requirements such as expandable and collapsible, multi-tier, multi-chamber tents spanning areas of thousands of square feet. We also provide a wide array of radiation containment products including portable containment tents as well as glovebags and catch containments.

Safer Work Environments

See how our containments can help prevent the potential spread of contamination.

LI-360A Dual Chamber Tent

LI-361B Dual Chamber Tent

LI-362 Single Chamber Tent

LI-363 Dual Chamber Tent

LI-300-POP-6×6

LI-300-PATCH KIT

LI-300-MOD KIT

LI-300-FP

LI-300-FS

LI-300-FGS

Frequently Asked Questions About Containment Tents

As North America’s leading manufacturer of essential protective equipment, Lancs Industries has earned a reputation for quality over our 49-year tenure in the industry. Here we offer a brief overview of answers to some commonly asked questions.

Robust Protection is Non-Negotiable

For nearly five decades, Lancs Industries has developed radiation containment products, containment glovebags and containment tents for a multitude of workplaces across many industries. We have established long-standing relationships with many high-level clients, including the U.S. Navy, NASA, and numerous National Laboratories. Please contact us today so we can find the best containment solution for your worksite.

Safer Work Environments

See how our containments can help prevent the potential spread of contamination.