Quality and customization

Glovebags & Containments

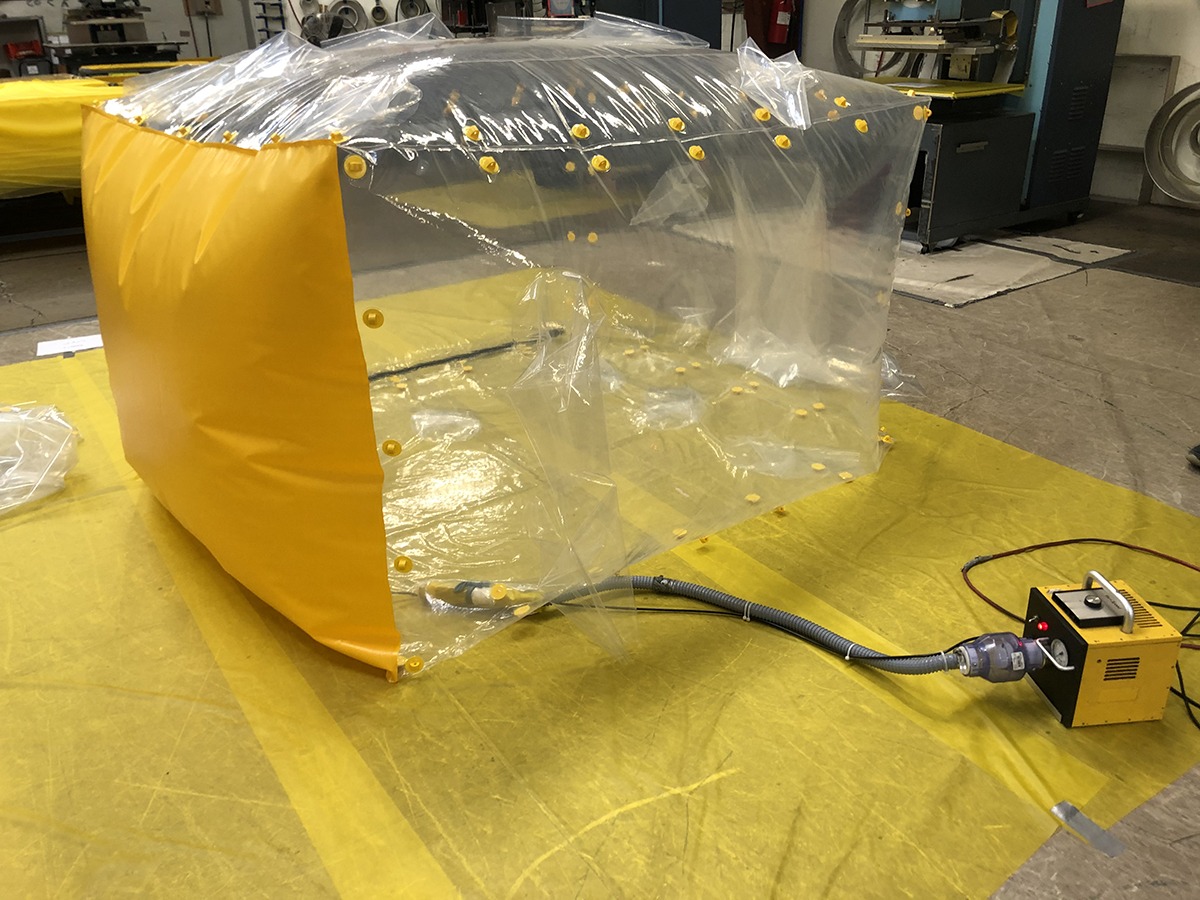

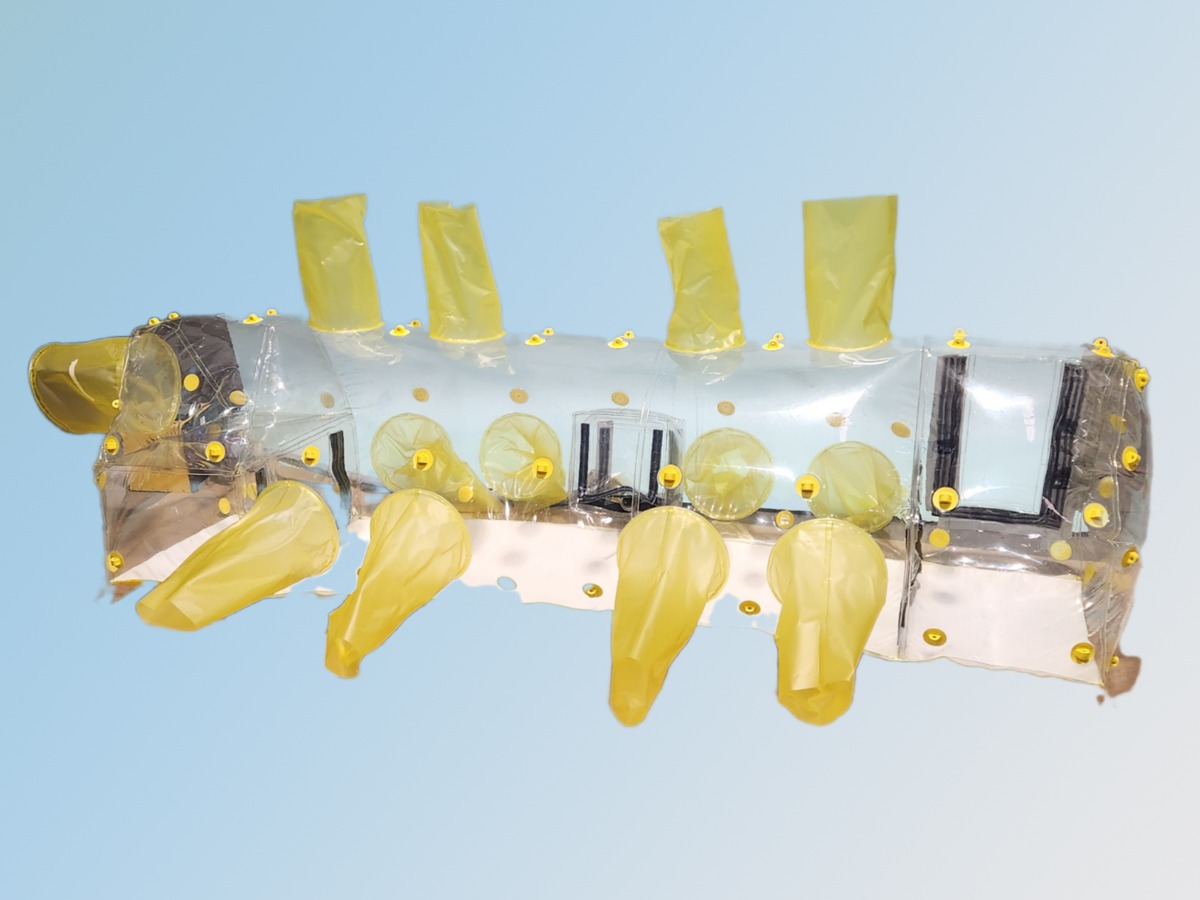

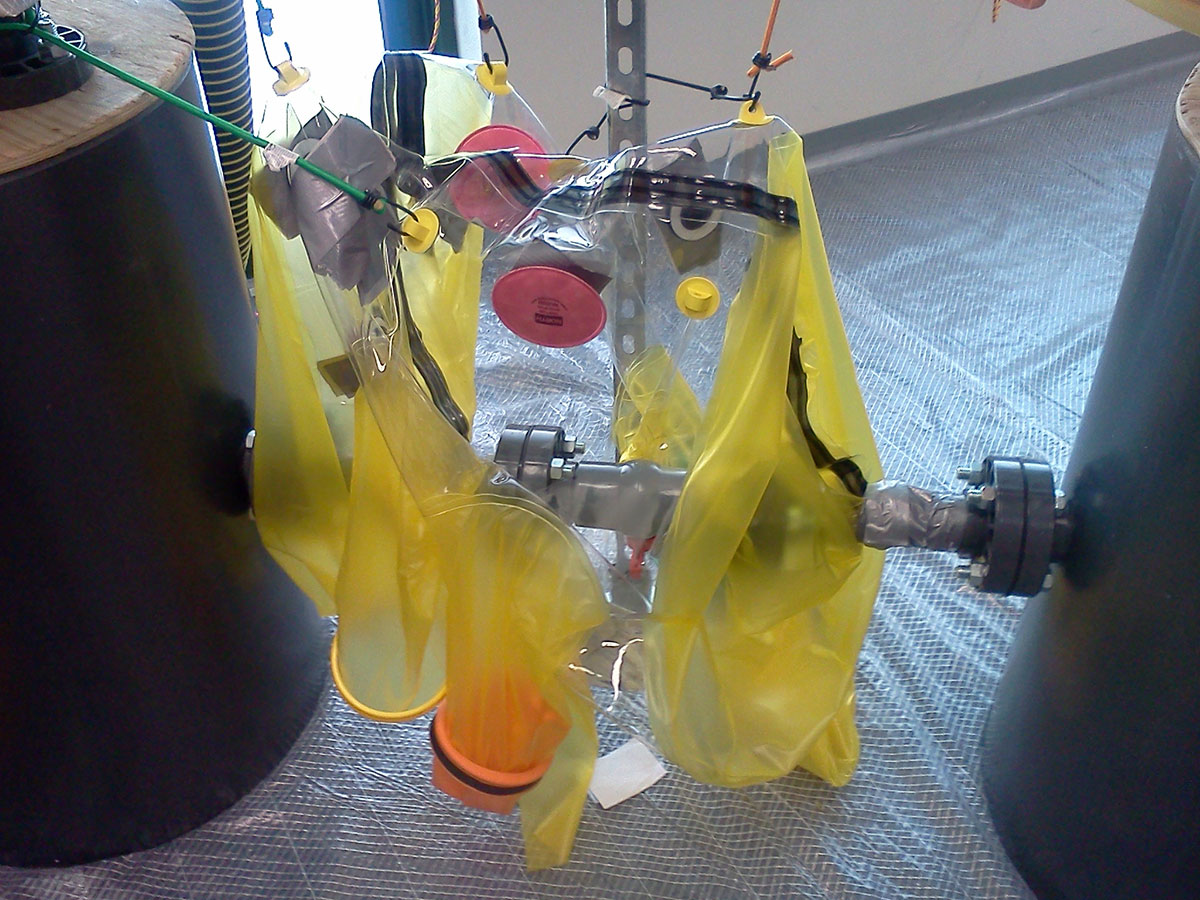

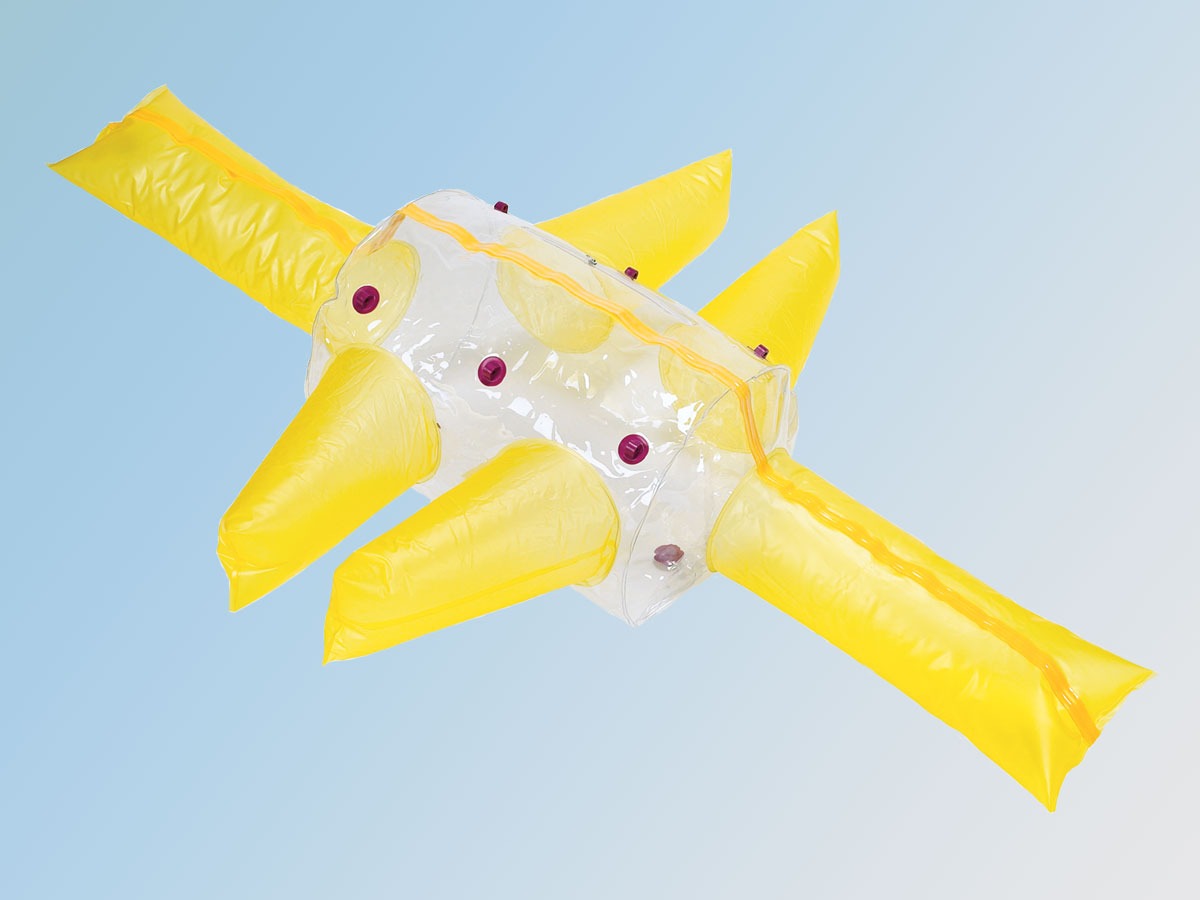

Glovebags are flexible radiation containments that enclose a contaminated item or form a small work area to confine the spread of contamination. Glove bag containments allow work to be performed on potentially contaminated items by personnel wearing a minimum of protective clothing. Access to the glove bag interior via gloved sleeves enables repairs or manipulations without directly contacting contaminated surfaces.

Lancs Industries makes a wide variety of glovebags with different configurations and dimensions. These designs have been developed throughout many years of experience with the U.S. Navy nuclear program, electrical utilities, and DOE lab facilities, to name a few.

Review the following standard glove bag designs for one that fits your needs. We also create custom-tailored glovebags as well as containment tents, catch containments and more. Lancs Industries can produce almost any unique configuration to meet your project needs.

Pro Tip: How to change out a damaged glovebag!

The glovebags shown are fabricated with the following general characteristics:

- 12 mil or 20 mil clear PVC or Polyurethane, fire retardant

- 8 mil or 12 mil translucent yellow PVC or Polyurethane, fire retardant

- 1" dia disk with light duty injection molded PVC eyelet

- Assembled by means of radio frequency heat sealing to ensure highest quality construction. Inflation pressure tested to verify containment seam integrity.

- Note: Images show sleeves with sealed ends for illustrative purposes only. Actual items have open sleeves.

Control contamination

Learn more about our wide variety of glovebags with different configurations and dimensions.

LI-300-BOB

LI-300-363624

LI-301 Single Chamber Work Containments "Doghouse Glovebag"

LI-301F Doghouse Glovebag External Frame And Drip Pan

LI-302 Glovebag

LI-303 Glovebag

LI-304 Glovebag

LI-305 Glovebag

LI-306 Glovebag

LI-307 Glovebag

LI-308 Glovebag

LI-309 Glovebag

LI-310 Glovebag

LI-311 Glovebag

LI-312 Glovebag

LI-356 Catch Containments

LI-351 – LI-355 Catch Containments

Frequently Asked Questions About Glovebags

As the longest tenured and largest manufacturer of flexible radiation containment products in North America, Lancs Industries supplies glovebags to worksites in need of customizable contamination confinement products.

Here, our experts answer some of the most frequently asked questions about these essential products.

Glovebags are flexible containments in which essential work can be performed on items that are contaminated by radiation. These enclosures can feature gloved sleeves that allow access to the interior of the contained space. Glovebag systems are designed to offer unrestricted movement within the interior of the enclosure, while preventing contaminants from escaping.

Custom glovebags have a variety of applications, including:

- Temporary containment of pipe leaks

- Repair of small, intricate components

- Replacement of contaminated gauges

- Removal of reactor core baskets

- Draining and venting processes

The design of our glovebag systems was born out of long-standing experience with the U.S. Navy nuclear program. As a result, worksite personnel can rest assured that our enclosures meet the most rigorous standards when it comes to safety and protection.

Larger containment systems play an integral role in worksite protection, but glovebags are the preferred option in certain situations. These systems reduce the need for full-scale personal protective gear, which can be cumbersome to wear and expensive, and can sometimes hamper staff during the course of their duties. This is especially true when it comes to the repair of small components.

Glovebags also increase productivity, as work can continue unabated around the enclosure thanks to the protection it affords workers near the area of containment. Use of glovebag systems makes for a more efficient worksite, which in turn saves your project money on operating costs.

The protection offered by glovebags can be enhanced when workers utilize best practices:

- Get Familiar with the Process/Procedure – Reviewing the repair process is recommended to ensure the proper procedures are used within the glovebag. The more familiar you are, the less likely you will be to make an error or forget a step in the process.

- Work Slowly and Carefully – While designed for maximum movement and efficiency, working in gloved sleeves can take some acclimating. By being meticulous and careful with your movements, you can avoid mishandling components or causing further damage to your component or to the glovebag.

- Handle Tools Carefully – Because tools will be contaminated after use within the glovebag, they must be handled carefully. With hands still in the gloved sleeves, grasp the tools and pull the sleeves inside out. Twist the sleeves containing the tools and seal the area above them using a strong adhesive. Next, cut off the sleeve above the sealed area and transfer tools to the decontamination unit.

Prior to disposal, contaminated air should be removed from the glovebag using a negative air vacuum. Next, twist and seal the lower portion of the bag to isolate any remaining contaminated materials. Place the used glovebag into the proper waste disposal bag and seal the disposal bag tightly. Fold the disposal bag and seal again, then disinfect the exterior of the disposal bag before discarding.

Quality Containment Products You Can Trust

In our nearly 50 years in the containment products industry, Lancs Industries has established an impeccable reputation for quality, efficacy, safety, and professionalism. Our glovebags can be customized according to your exact design specifications, or we can help you develop a suitable design based on your needs. We also develop customized containment tents, radiation shielding and more. Contact us today for more information.

Control contamination

Learn more about our wide variety of glovebags with different configurations and dimensions.