Contact Us

Blog Short Form

"*" indicates required fields

When planning for radiological work on piping and valves, one essential tool to consider is the use of a glovebag. Glovebags can be indispensable in environments where radiological contamination is a concern, as they provide a controlled environment for the work area, reducing the potential for contamination spread. However, a common misconception is that glovebags take too long to set up or are overly complicated to install. This perception can deter workers from using them, despite the significant protective benefits they offer in managing contamination risks.

Containment Glovebag Key Design Points

To address these concerns, Lancs Industries has designed glovebags specifically to streamline installation and ease of use. Two notable models, the LI-304 and LI-338 glovebags, are particularly suited for work on pipes and valves. These models feature a continuous Velcro strip, which allows for a quick and easy setup process. Workers can wrap the glovebag around the pipe or valve, install the necessary tools within the glovebag, seal the Velcro strip, and then secure each end with tape. This design makes it much simpler and faster to put into place compared to traditional methods that require more extensive sealing and fastening.

The LI-304 and LI-338 models share the same shape but differ in size to accommodate different pipe dimensions and work requirements. The LI-304 model measures 18 inches in diameter and 24 inches in length, making it suitable for smaller pipes or more confined spaces. Meanwhile, the LI-338 is larger, with a 24-inch diameter and a 36-inch length, providing a roomier workspace for more extensive maintenance tasks. Both models ensure that radiological contamination is controlled, offering a safer environment for workers while also minimizing the risk of contamination spreading to other areas.

Once the Velcro strip on the glovebag is sealed, it’s crucial to reinforce the seal to prevent any possible escape of airborne contaminants. Since the Velcro closure itself is not completely airtight, additional measures are needed to secure it. Many facilities opt to add a patch over the Velcro, using either a strong adhesive or tape, to enhance the seal’s integrity. Some even apply a specialized sealant, such as RTV (room temperature vulcanizing) silicone, to the Velcro strip before fastening it. This added layer of sealing helps to ensure that any potential airborne contamination remains contained within the glovebag, thereby creating a safer work environment. Despite these extra steps for reinforcement, the entire installation process generally takes only a few minutes.

Custom Glovebag Containment Options

Beyond standard sizes, Lancs Industries also offers custom glovebag options to fit unique pipe dimensions or specific project needs. This customization allows facilities to tailor glovebags to their precise requirements, and additional features such as waste sleeves, HEPA filter sleeves, or drain connections can be incorporated. These accessories further aid in containment and make it easier to safely dispose of or handle any waste generated during the work.

The use of glovebags has become increasingly important in industries like nuclear power, where radiological safety is paramount. Historical incidents highlight why robust contamination controls are necessary. For example, there were at least two cases at power plants where contamination spread significantly when workers conducted grinding operations inside piping. These incidents involved cutting the pipe and grooming it for a butt weld, during which workers used a motorized wire brush or flapper wheel to remove debris and corrosion. Unfortunately, the disruption of the oxide layer inside the pipe caused fixed contamination to loosen, allowing it to spread throughout the work area and onto the workers. Such incidents underline the importance of effective contamination controls, especially during operations that can disturb contaminated surfaces.

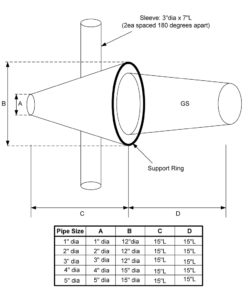

In response to these challenges, Lancs Industries developed a specialized grinding glovebag in collaboration with personnel from the Palo Verde Nuclear Power Station. This glovebag model is designed to prevent contamination spread specifically during grinding or other grooming operations on pipes. The glovebag allows workers to complete necessary tasks within a controlled environment, containing any loose contaminants that might otherwise escape into the surrounding area. Once the job is completed, the glovebag can be untapped and removed from the pipe safely and easily.

Lancs Industries’ custom design options allow facilities to order glovebags of any size and configuration to suit their specific needs. This flexibility ensures that whatever the dimensions or requirements of a job, a glovebag can be created to provide a secure, contamination-controlled environment. The use of glovebags like the LI-304 and LI-338 models, as well as custom designs for unique applications, demonstrates how this technology can play a critical role in ensuring safety and contamination control during radiological maintenance and repair tasks. By making glovebags easier and quicker to install, Lancs Industries is helping to break down barriers to their use, encouraging safer practices in handling potentially hazardous materials.

About the Author:

Learn more about Lancs Industries and how they have been the leaders in radiation shielding for over 50 years. Find out more about their founder, where they've been and where they're going.

Contact Us

Blog Short Form

"*" indicates required fields

Subscribe to our Newsletter

Get industry updates and new blogs straight to your inbox.

"*" indicates required fields